About Blade Finishes

Blade finishes to a knife are a unique and personal choice, with many options being available on the market. Some of the finishes will claim benefits like lower reactivity or food release, but none of them are magic pills for taking care of the knife. Once you understand that, finding the finish that you enjoy the most is a fun experience.

The majority of special finishes for knives originated in Japan, or were popularized by the cutlery of Japan. You will find below all of the terms are Japanese in origin, however they may apply to knives from anywhere by different names. The list below should still function fine to get an idea of different knife finishes.

Due to the hand made nature of high end knives, each finish will be different not only in how the blacksmith forged each knife, but also in how the process was finalized by the sharpener. Below is an overview of the types of finishes you will find on different knives. Finishes do vary greatly even amongst the same type based on make and style, so do some looking around and ask questions of your retailer!

Blade Cladding Types

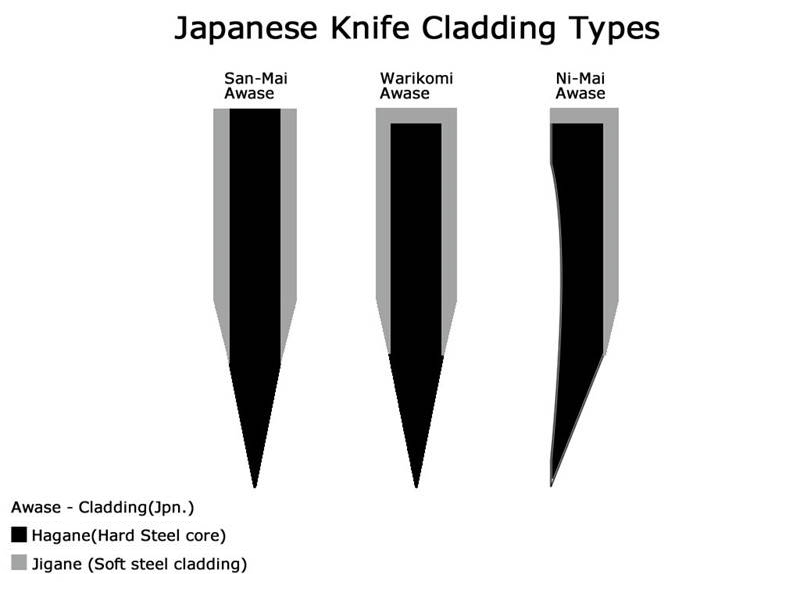

San-Mai

San-Mai is a traditional, high end Japanese blade making technique in which a hard steel blade core is clad with a single layer of softer steel on each side of the core for support. This helps the hard and brittle core metal absorb shock from use and avoid cracking. Sometimes the softer steel used is a stainless variety to also help with corrosion resistance. Obviously, in the stainless varieties only the exposed core blade will develop patina rather than the whole blade doing so. In this style, the three pieces of metal are flat against each other and the spine is not wrapped with the softer steel.

Warikomi

Warikomi is almost exactly like San Mai, however the spine is also wrapped in the softer steel cladding.

Ni-Mai

Ni-Mai is similar to San-Mai and Warikomi however the softer steel cladding is present along only one side and the spine of the blade. In this case, the side without the softer steel cladding is usually hollow ground and the whole blade is single bevel.

Blade Finish Types

Kasumi

Kasumi is a light hazy finish which changes based on metal type. Kasumi roughly translates to haziness or mistiness. This finish is used with San Mai blades where there is a softer steel cladded onto a harder steel at the edge of a knife. The kasumi finish will polish the hard steel and soft steel at different rates, leaving the soft steel cloudy and the hard steel brightly polished. It is very beautiful and one of the most attractive qualities about new Japanese knives. This finish is made on the whetstone itself, and while it can be done on synthetic stones is far easier to do on Japanese natural stones. The qualities of the haziness and polish will differ based on the hardness and fineness of the stone it is polished on. It is important to note that the kasumi finish is often quickly hidden under the natural patina developed by a knife, but can be returned with further polishing if desired.

Kurouchi

Kurouchi is a traditional rustic finish. Kurouchi roughly translates as blacksmith’s finish. Kurouchi knives retain the scaly residue left from the forging process. The finish reduces reactivity on carbon steel knives, reduces the cost of production, and gives the knife a very characterful, rustic aesthetic prized by many knife enthusiasts. Kurouchi finishes vary widely in appearance, uniformity, and durability. Kurouchi also has texturing under the black finish to help with food release.

Nashiji

Nashiji is a textured finish. Nashiji roughly translates to pear skin. The finish is meant to help food release by creating a surface that isn’t perfectly flat against the cut food. This finish is created by starting with a Kurouchi finish and polishing off the black finish, leaving just the textured finish behind. A Kurouchi may turn into a Nashiji over time as the black finish naturally wears off.

Tsushime

Tsuchime is a highly textured hammered finish. Tsushime roughly translates to hand hammered. These finishes can vary greatly depending on hammer profile and force used behind it. It has the same benefits of Nashiji with helping food to release and can be more pronounced if the hammering was done heavily.

Suminigashi

Suminigashi is also known as Damascus. This finish creates a unique pattern on the profile of the blade usually in the form of lines and circles. This finish is achieved by layering two different types of steel together, hammering it out, welding it and then folding it over onto itself. This is done multiple times to create the patterns seen on the blade which represents those fold marks. Often after this process is done, cheaper blades will be acid etched to more prominently show the Suminigashi contrasts. This finish does not help the performance of the blade in any discernable way and is purely aesthetic. It is also important to note that this is not the Damascus finish from historical contexts, it is a finish emulating the look of that ancient steel. Historical Damascus came from a specific ore mine with special attributes where, upon being forged in a specific manner, small carbon nano-tubes ran throughout the blade. Suminigashi does not achieve this.

Migaki

Migaki is the most common finish type and is of a high sheen. Migaki translates roughly to polished. There is a lot of variance still in this type of finish based on polishing methods and compounds used. It can range from a matte to mirror polish as well as different direction of polishing strokes. This finish does not help the performance of the blade in any discernable way and is purely aesthetic. The closer to mirror polished the knife is, the easier new scratches will show on it’s surface.